the company

DOTCOAT is an engineering company which is solely focused on solvent free coating and lamination technology.

Due to the taking over of the complete machinery program of the company S-LINE ( formerly known as SCHAETTI – LINE ), including the well known flatbed lamintion technology from KANNEGIESSER, we are able to offer the most relvant adhesive coating and laminating processes needed for the production of a huge variety of laminates and composite materials.

01

but also deliver entire new roll to roll or non stop operation plants

02

We Retrofit secondhand equipment

03

We upgrade or rebuild existing equipment

more than an Alternative

Here some remarkable brands, who have recently decided to work with DOTCOAT machines:

What Our

Customers Say

We consider our projects to be exciting tasks that we are happy to implement with the utmost care. Here we would like to give you a little insight into past orders and related customer comments. If you would like to know more about the individual projects, we will be happy to put you in touch with the respective customer contact, just give us the associated order number.

Project 0367:

Impregnation and cutting system for phenolic resin on glass fabric for the automotive industry.

“For a model series in the premium automotive segment, we had to aquire a tailor-made system that we found at DOTCOAT. Despite our special requests, we received a very good price / performance ratio."

Project 0370:

Coating system for cosmetic articles on nonwoven substrates.

“We had no knowledge of how to implement our customer's requirements. DOTCOAT designed and delivered the right system for us. Our product comes out of the system exactly as requested."

Project 0380:

Flat bed laminating system for processing a wide variety of materials in the commission coating and laminating business.

“The system supplied by DOTCOAT meets all of our requirements. A small but positive detail is the low height of the laminating machine. This makes communication easier and improves the working atmosphere in the production area."

Project 0381:

Laminating line for the production of high quality hygienic protective clothing.

"Outstanding process knowledge and good mechanical engineering at DOTCOAT have provided us with a system with which we are one step ahead of our competitors in terms of the quality of our products."

Project 0385:

Laminating and calibration system with an extremely high accuracy for UV lacquer coating on aluminum sheets for the automotive industry.

“We only had a rough hand sketch of the processes that we needed for our UV paint coating system. DOTCOAT has implemented the requirements in full and also analyzed and constructively eliminated all other process risks ... .good job ... "

Project 0389:

Scatter coating system for leather skins in 3 m width for automobile interiors.

"The system fulfills our specifications 100%, as a supplier we got to know DOTCOAT as being absolutely competent and innovative."

Project 0394:

Laminating machine for various foam, textile, paper and fleece combinations. Self-adhesive - finishing of substrates.

“We needed a small machine that we couldn't find on the market. DOTCOAT has understood our wishes and implemented them very well in a special machine."

Project 0397:

Scatter coating and lamination system for the finishing of wooden panels in 3 m working width.

"In our project to laminate wooden panels with foils, DOTCOAT helped us not only to design the right concept, but also to find suitable adhesives and substrates through trials and advice."

TECHNOLOGY

GRAVURE ROLL

A heated gravure roll transfers the hot and thus liquifed adhesive onto the substrate to be coated in a structured form. Most often, the adhesive is applied in dots, nets or line - structures with many different parameters.

machinery EXAMPLES

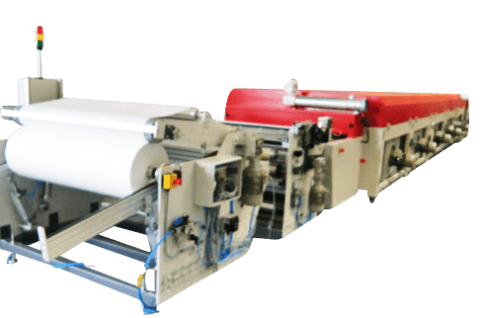

Continues Hotmelt- Coating and Laminating line, with roller accumulator for in- and outlet. With semi-automatic winding unit. For the production of anit-slip coatings for non-wovens, abrasive coatings for disposable wipes or EVA coatings for various substrates.

SLOT DIE

Melted adhesive is pumped through a heated slot die. At the lip of the slot die the adhesive is applied to the substrate`s surface. Depending on the amount of adhesive lay-down and speed, the adhesive is transferred in open or closed film structure.

machinery EXAMPLES

Hotmelt – slot die coating machine for the production of full or open hot melt adhesive coatings or laminations. Serves a wide variety of substrates with self-adhesive, thermoplastic and reactive hotmelts.

FLEXO COAT

A heated roll transfers the hot liquid adhesive onto the substrate. By a differential speed between

substrate and application roller, it is possible to decrease or increase the application amount, thus

decreasing or increasing the coating weight.

FLEXO COAT System:

Coating weight adjustment

- within seconds adjustable

- with the same gravure roll

- from 1 - 200 g/m² (depending on substrate and adhesive)

SPRAY BAR

The heated spray bar is fed by a gear-pump with the liquifed adhesive. The adhesive, leaving the nozzle, is dispersed by pressurized air. Without contact, the adhesive is transferred to the surface of the substrate passing by. Depending on speed and adhesive amount, an open or closed adhesive layer can be created.

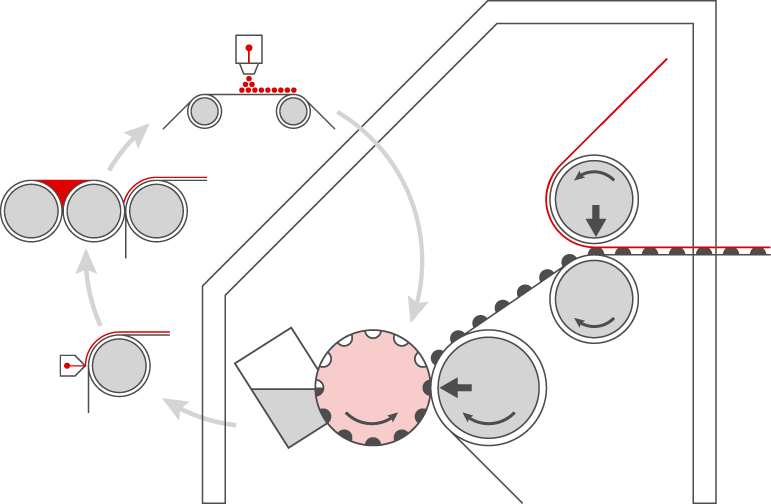

POWDER SCATTERING

A rotating, structured roller is filled with thermoplastic powder. Depending of the required coating weight, the rotation speed is adjusted. Right after, an oscillating brush empties the roller and this way, the volumetrically dosed powder falls onto the substrate passing underneath.

machinery EXAMPLES

Powder scattering system, with scatter coater, IR-oven and smoothing and cooling calander. Possible options such as swiveling powder hopper, automatic powder feed, and recycling plants can be useful additions to a complete system. Diverse applications such as automotive interiors, interlining, thermoplastic pre – coatings, carpet backing and foam lamination as well as many other applications are possible with this technology.

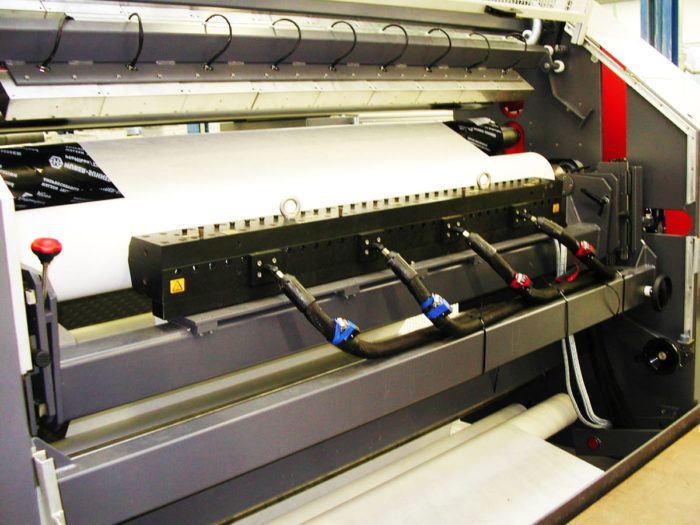

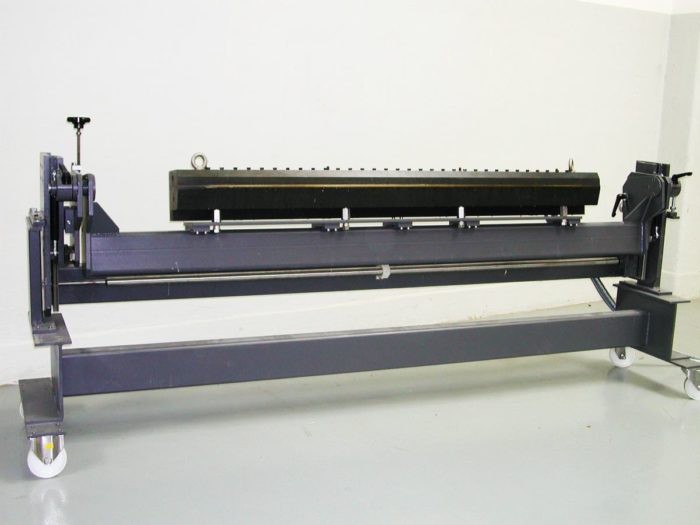

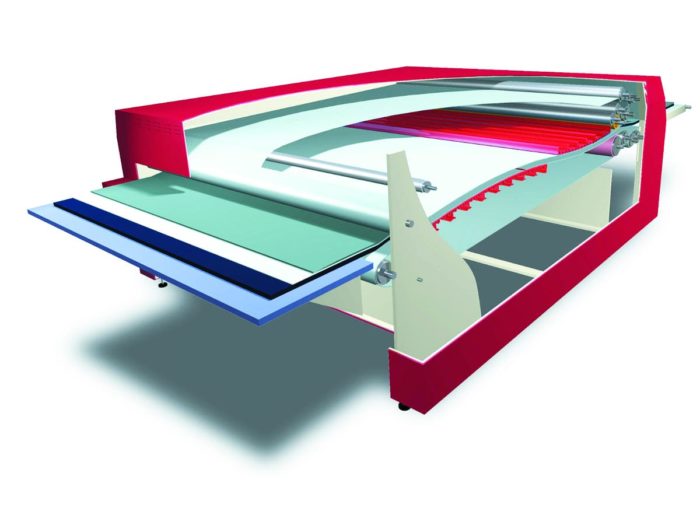

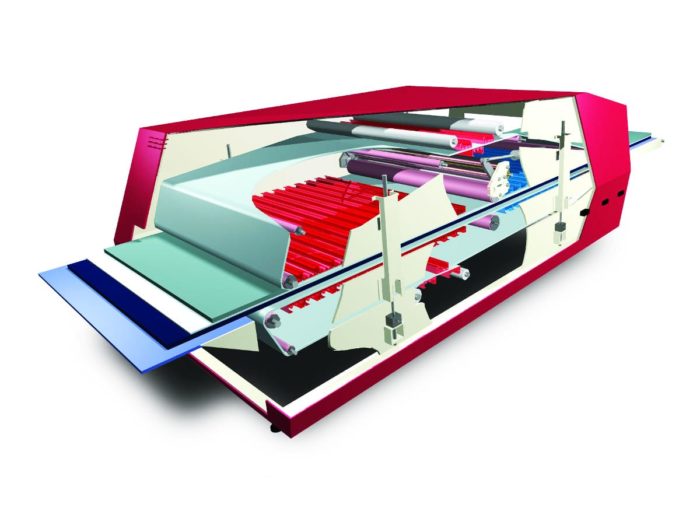

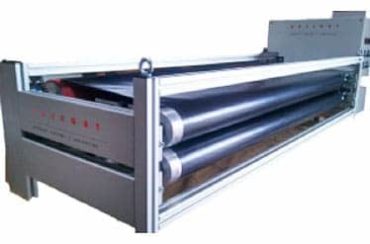

FLAT BED LAMINATION

In order to coat or laminate various substrates, the material is transported between two belts through a heating section. This way, the thermoplastic adhesive, applied before the machine in form of powder, webs or films is melted. Most often, the heating section is followed by a calandering unit and a cooling section. This way, the liquifed adhesive is squeezed into the surfaces where it solidificates by cooling and thus glues the substrates together.

machinery EXAMPLES

Flat bed laminating system, with heating and cooling section and integrated laminating calander. Optional height adjustment of the laminating machine up to 150 mm throughput height. Configurable for rolls and sheets. For the production of various laminates, for the consolidation or calibration of various substrates, or as a preheating station for compression molding.

POWDER DOT

A heated gravure roll runs under a powder filled funnel. The funnel is equipped with doctor blades, so that the roller is stripped off from remaining powder, when it is leaving the funnel. The fabric to be coated is heated up to pick up the powder provided from the relatively cooler gravure roll, when it is getting in contact.

PASTE & DOUBLE DOT

A rotating screen runs over the substrate to be coated. Inside the screen is a squeegee blade. Through a pipe system, paste or other dispersions are fed into the screen. By the rotation of the screen, the blade pushes the paste through the holes of the screen and coats the substrate. In case of a double dot system, powder is fully coated onto the substrate right after the dot coating. Afterwards, the exceeding powder captured by the wet dots is sucked off.

System EXAMPLES

Highly efficient single-layer coating machines in powder dot, paste dot and double dot method. Hot air dryers for wet coatings, followed by paste dot or full surface coating machines. For the production of anti-slip coatings, abrasive functional coatings or many other applications.

EXTRUSION

In order to make foam sticky enough for bonding with other substrates, the surface of the foam needs to be burned by a fame system, generated by pressurized or natural gas. Depending on the thickness of the foam to be burned, the production speed and burner settings are to be chosen. Right after the buring section, the foam can be laminated with almost all substrates.

MELTING EQUIPMENT

Our various melting - and metering systems are used to liquify the adhesives, which are available in various forms like drums, blocks, pillows, granules and bags. Most often, tank- or drum melters are used for this purpose. Heated pumps and hoses feed then the melted adhesive to the different application systems.

System EXAMPLES

For liquefying the hotmelt adhesive beside the machine. Tank melting equipment, barrel melting equipment and extruder technology. Different sizes and performances. Custom-made to specification.

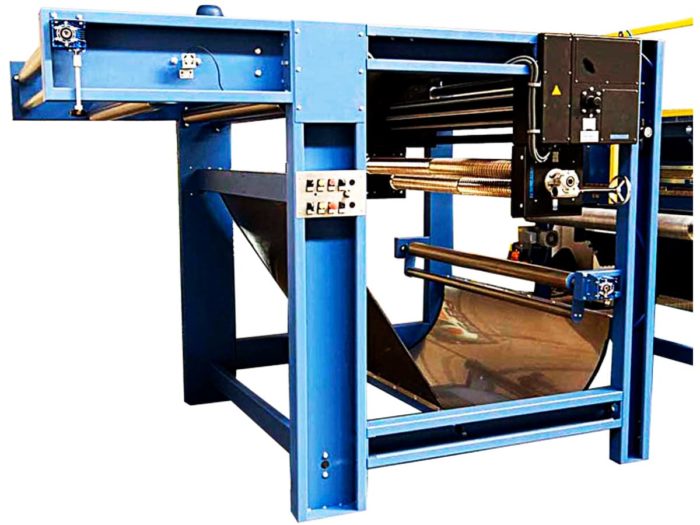

ACCUMULATION & WINDING

In general, for most materials we handle, winding and often accumulating equipment is used. We do therefore offer all common accumulation systems, like roller or belt accumulation, as well as J-Box systems. For the winding we supply simple unwinders with manual break, but also traditional surface or center winders, and where sensible even semi-automatic winding units.

machinery EXAMPLES

Continuous hotmelt laminating system for breathable membrane film laminations. Areas of application are e.g. outdoor clothing, incontinence products and roof underlays. For continuous operation, J-box and flat-belt, or even roll – goods storage are used. As winders, circumferential or center winders are available. Either manually, semi-automatically or fully automatically.

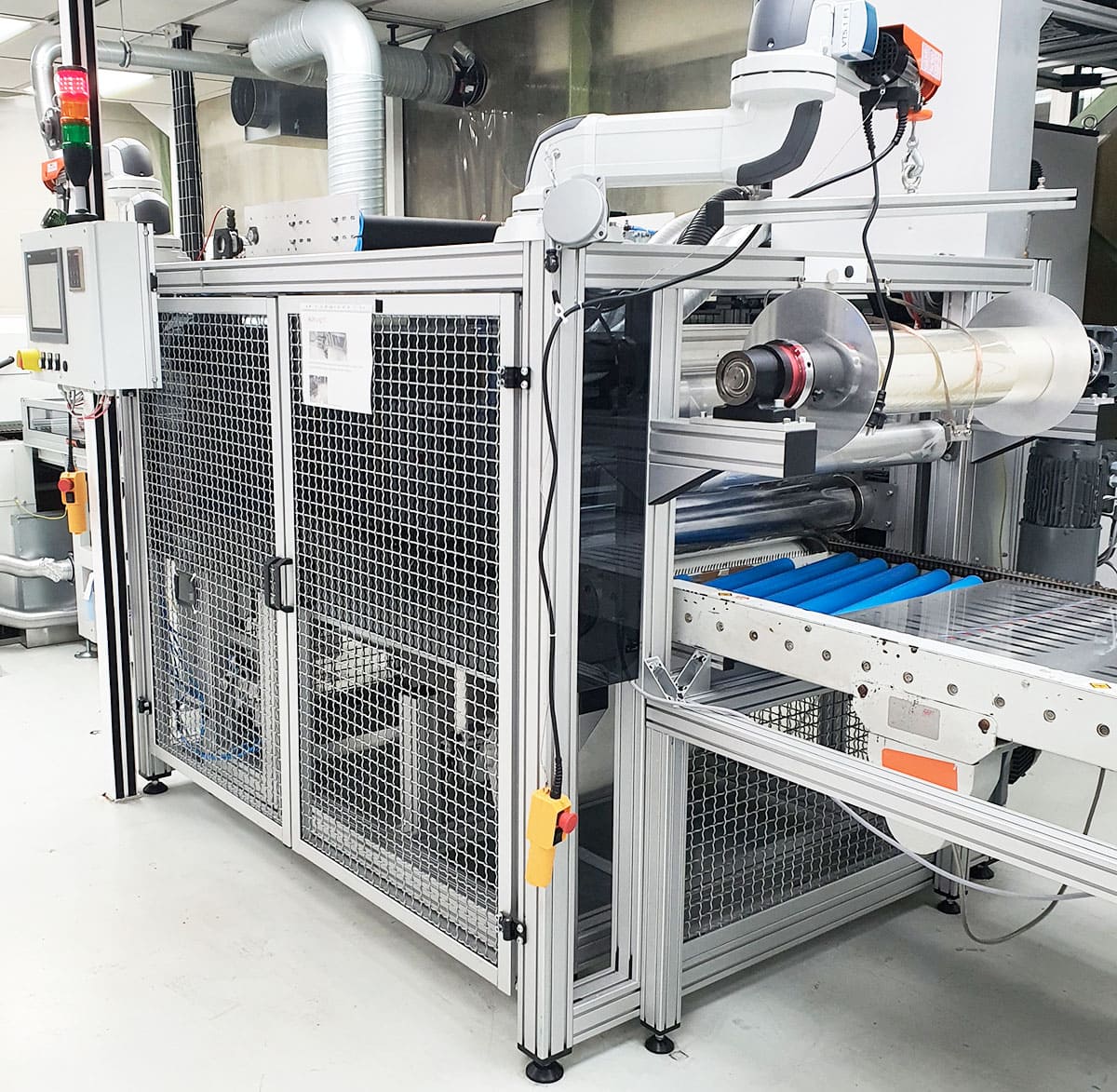

CUTTING & STACKING

In case of need, we supply cutting systems working under the pressure or sissor cut principle. Either for the use of edge cutting or for multiple cuts for any substrates. When sheeted material needs to be used, we design tailor made handling systems, working with many different gripping systems.

SPECIALS

For special customer requirements, we often develop and build special equipment. We use components from our existing modules, or we also construct new solutions that are tailored exactly to the needs of our customers. Here some recently developed examples:

MODULAR

We are always working to make our systems even more modular. This means increased flexibility for our customers, now and for the future.

One frame for various

application technologies

such as gravure roller and slot die but also combined with spray nozzles, VarioRoll etc.

Time is changing and with it your needs for your process capabilities!

For you to be prepared with your new investment for future market needs, we offer all our standard machinery and plants in a modular design.

Regardless, whether you start with gravure roll technology and you have to change or upgrade later to slot die or spray system, you have this option with our technology at any time and at reasonable cost.

A change of the application system is quick and easy done. You can use the same plant with just changing the application technology and you will add much more flexibility to your product range.

By the way: our flatbed machines are as modular as our Hotmelt machines. Contact us to learn about the advantages.

Over

25

years

experience

APPLICATION

Coating and laminating is applied in many high level industry sectors, where products are in use, such as:

- breathable laminates for outdoor wear

- laminated fabrics for protective clothing

- fashionable clothing e.g. lingerie

- fusible interlining for apparel industry

- laminated textiles for automotive interior

- foam and nonwoven laminated textiles and film for furniture, carpets, etc.

- nonwoven coating and laminating, e.g. isolation material, anti-slip-layers, geo-textil, etc.

- medical reusable and disposable materials

- self-adhesive coatings on film, foam, textiles, papers and nonwovens

- shoe interlining

- coated and laminated fabrics for a wide range of industrial use, e.g. filter media, abrasive material, book lining, etc.

- functional coatings for cosmetic products

- coating and laminating of industrial tapes

- glas and carbon fibre material coating and laminating for composites

- leather coating for steering wheels, shoes and apparel

- aluminum coating and laminating

- carpet and carpet back coating and lamination

Adhesive application finds it’s place in many different industries. Most often they share the same goals:

Substitute

solventor water based adhesives

Create

new products

Improve

performance of existing products

Save resources by

technological change to

hotmelts

Improve

the processing of

products

Dotcoat GmbH

Döbelistrasse 6

CH – 8280 Kreuzlingen

DOTCOAT Europe GmbH

Wilhelm-Maybach-Str. 6

DE – 78234 Engen